Steam drum is a vital part of boiler system in chemical industries. Proper and safe functioning of boiler depends on various parameters such as level of steam drum, flow of feedwater and flow of steam. The pressure, temperature and level of boiler system cannot be regulated directly but depends on the feed-water flow. The pressure or temperature in a boiler system can be maintained by controlling the flow of fuel and air whereas the level can be maintained by regulating the flow of feed water. The purpose of drum level controller is to keep the level at desired value, optimal interface level requires between steam and water within the steam drum. It is essential that the level of liquid must be low enough to assure that there is appropriate separation between steam and water and high enough to guarantee that the water exists in every steam generating tube.

In this blog we will show the 3 most common drum level control schemes and what tuning strategy you should adopt for every strategy.

Components of Steam Drum Level Control

There are various components that affect the level of steam drum:

- The bubbles exist under the interface level between steam and water into the steam drum due to boiling of water.

- The increased/decreased volume of steam bubbles leads to the variations in water level that result in the phenomenon of ‘false water level’.

- steam drum pressure. The contraction or expansion of steam bubbles depend on the variations in steam drum pressure due to changes in the steam demand.

The design of the boiler drum level control strategy is normally described as:

- Single-element

- Two-element

- Three-element control

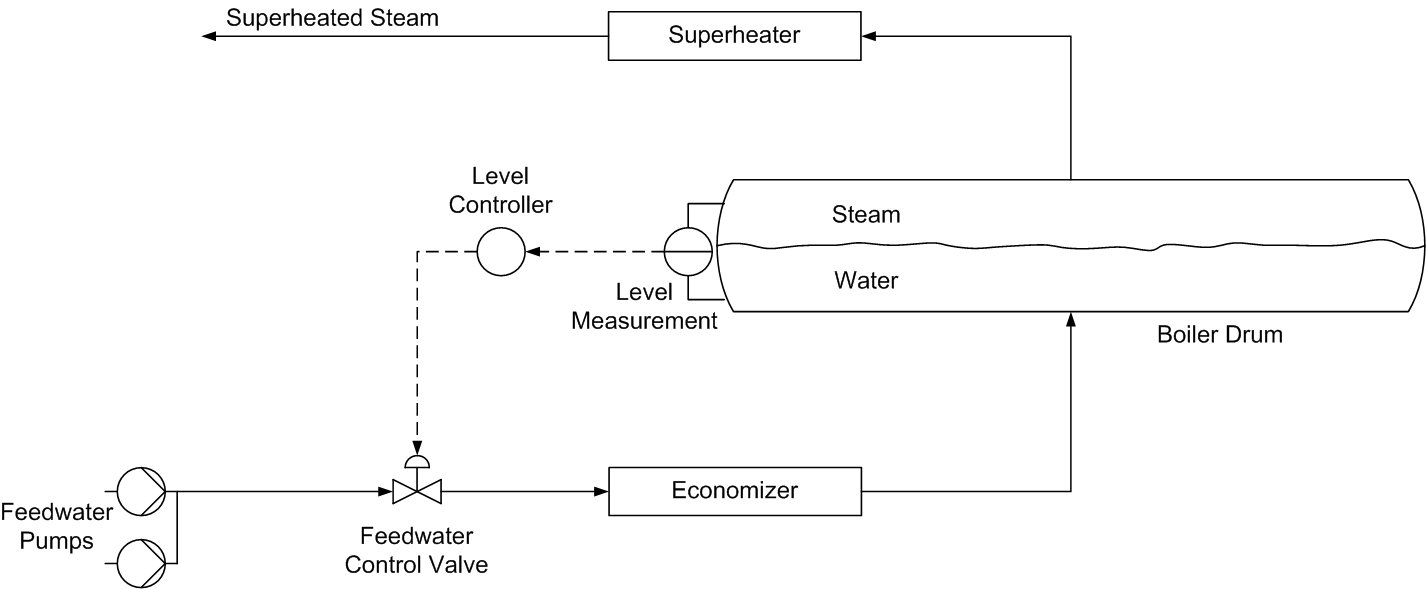

1. Single Element Drum Level Control

The first design: Single Element Drum level Control' is explained below

Scheme

Single element drum level control is the easiest strategy suitable for small boilers that have low and moderate variations in load/disturbances. In this approach, the level is being measured that helps in controlling the flow of feed water to maintain the steam drum level. Due increase or decrease in demand of steam, phenomenon like swelling & shrinking occur in steam drum which makes boiler operation tedious. The drawback of this approach is that level of steam drum is affected by uncontrolled feed water and steam disturbances.

PID tuning strategy

From a controls point-of-view, the boiler drum is an integrating process. This means that any mismatch between inflow (water) and outflow (steam) will cause a continuous change in the drum level. Integrating loops are difficult to tune and can easily become unstable if the controller’s integral time is set too short (i.e., high integral gain). The process-imposed requirement for a long integral time makes the loop slow to recover from disturbances to the drum level.

Addition to above, the boiler drum level is notorious for its inverse response. If the drum level is low, and more feedwater is added to increase it, the drum level tends to decrease first before increasing. This is because the cooler feedwater causes some of the steam in the evaporator to condense, causing the volume of water/steam to decrease, and hence the drop in drum level.

Conventional feedback control has difficulty in coping with this inverse response. A control loop using high controller gain and derivative action may work well in other level applications, but it will quickly go unstable on a boiler drum level. Stability is best achieved by using a low controller gain, long integral time, and no derivative. However, these settings make the controller’s response very sluggish and not suitable for controlling a process as critical as boiler drum level.

Drum level is affected by changes in feedwater and steam flow rate. But because of the very slow response of the feedback control loop, changes in feed flow or steam flow can cause very large deviations in boiler drum level. Single-element drum level control can work well only if the residence time of the drum is very large to accommodate the large deviations, but this is seldom the case – especially in the power industry. For this reason, the control strategy is normally expanded to also include feedwater and steam flow.

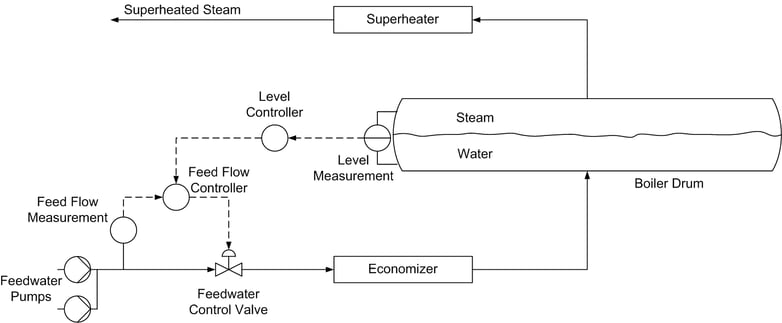

2. Two Element Drum Level Control

Scheme

Two element drum level control strategy is effective for the boilers with moderate variations in load. In double element level controlling the swelling and shrinking effect of boiler drum is taken care. Pressure of the drum varies according to steam flow. if load increases and drum pressure drops. In two element controller this effect is compensated by measuring steam flow along with drum level. Steam flow will give incorrect feedback if it is not compensated suitably according to stem pressure and temperature. Flow of steam has direct relationship with pressure and temperature. So, in most of the causes measurement of steam flow is compensated by pressure and temperature. The drawback of this strategy is that the disturbances due to steam drum pressure and variations in load cannot be adjusted in feed water supply as this variable is not measured in this control strategy.

PID tuning strategy

Many boilers have two or three feed pumps that will be switched on or off depending on boiler load. If a feed pump is started up or shut down, the total feedwater flow rate changes. This causes a deviation in drum level, upon which the drum level controller will act and change the feedwater control valve position to compensate. As explained above, the level controller’s response is likely very slow, so switching feed pumps on and off can result in large deviations in drum level.

A faster control action is needed for dealing with changes in feedwater flow rate. This faster action is obtained by controlling the feedwater flow rate itself, in addition to the drum level. To control both drum level and feedwater flow rate, cascade control is used. The drum level controller becomes the primary controller, and its output drives the set point of the feedwater flow controller, the secondary control loop.

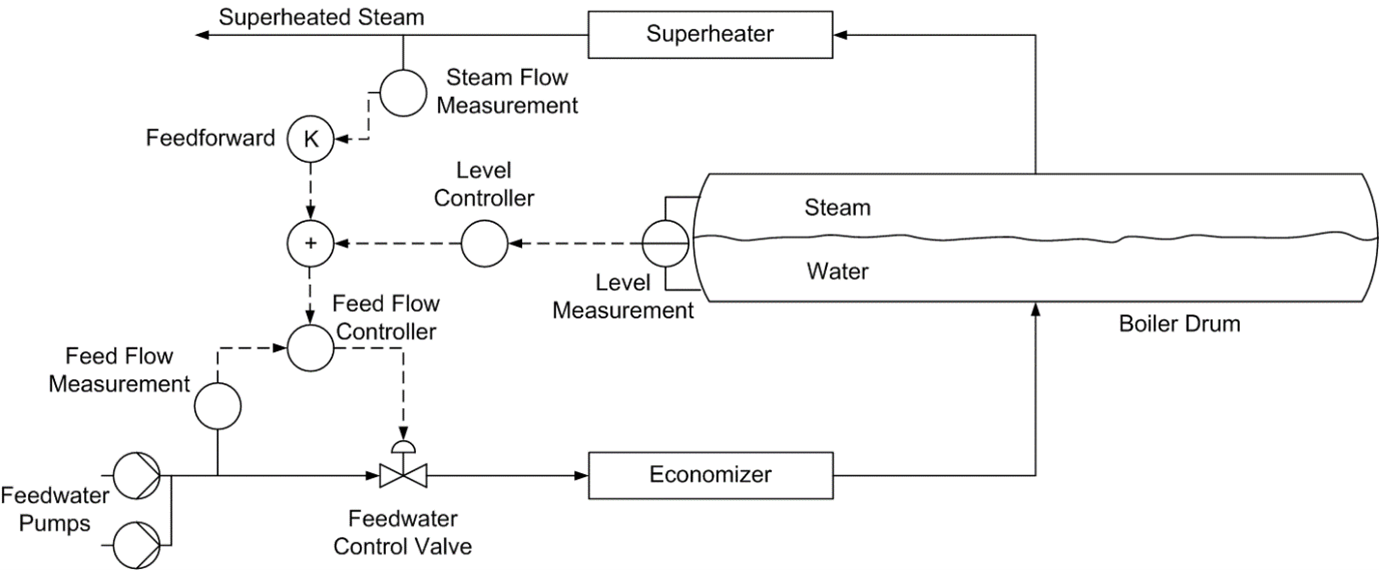

3. Three Element Drum Level Control

Scheme

A three-element boiler water level control system is one which typically uses the measured water level, the steam flowrate from the boiler, and the water flowrate into the boiler to regulate the flow of water into the boiler. It is a most common boiler drum level control strategy and effective to use three element drum level control so that shrinking and swelling effects can be taken care of. Figure 2.3 shows the control scheme of three element drum level control. The shrink and swell introduce the phenomenon of false water level that leads to the measurement of three parameters including drum water level, feed water flow and steam flow.

With the addition of feed water flow and steam flow measurement in the control system, one can easily determine any major discrepancy between the two and take the control action to maintain the water level. The same results can be attained by using two element control, but there are some disadvantages of two element control such as it cannot change for the load disturbances take place in feed water supply. Secondly, the phasing interaction between the drum level and feed water flow cannot be eliminated by the two-element control.

Thus, to deal with these issues, three element steam drum level control is used in which a third variable feed water flow rate is added which is used to manipulate the feed water control valve. The output of two element drum level controller is cascaded with feed water flow controller. The steam flow act as the set point to the feed water controller and feed water flow is used as the process variable. Thus, amount of steam leaving the drum results in the addition of equal quantity of feed water to the drum. The three-element drum level control strategy is effective for rapid variations in load because it can easily handle the balance between feed water flow and steam flow.

PID tuning strategy

Like feed flow, changes in steam flow can also cause large deviations in drum level and could possibly trip the boiler. Changes in steam flow rate are measurable and this measurement can be used to improve level control very successfully by using a feedforward control strategy.

For the feedforward control strategy, steam flow rate is measured and used as the set point of the feedwater flow controller. In this way the feedwater flow rate is adjusted to match the steam flow. Changes in steam flow rate will almost immediately be counteracted by similar changes in feedwater flow rate. To ensure that deviations in drum level are also used for control, the output of the drum level controller is added to the feedforward from steam flow.

It is a tedious & critical job to tune these controllers, Manual PID tuning require a lot of time & detail knowledge of loop interaction. PID tunning tools (Like Aptitune) makes it easy to tune these loops. One of the examples explained below.

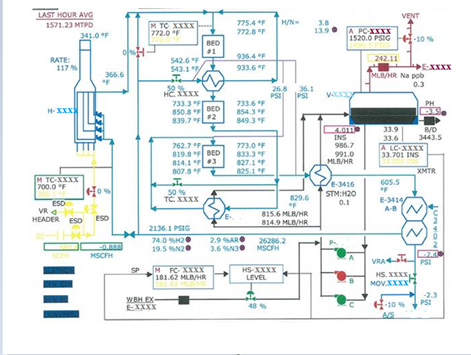

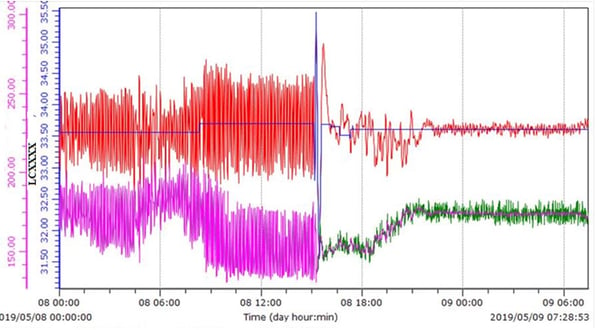

The above figuree explains the three-element control scheme where IPCOS has tuned & stabilized level with Aptitune software. As per control strategy drum level will be master loop & make up water slave, steam flow act as feed forward for tuning. The figure below shows the improvement in level with tuning.

Above all proposed schemes can be implemented easily in DCS by using the standard DCS blocks and calculations. Other than implementing a correct control scheme, it is equally important to tune the PID loops correctly and how it helps to stabilize drum level explain above with example. software can calculate the right parameters; you don’t have to look at it again. In the end, the software helps you achieve the desired result faster.

Like to get more information?

Would you like to receive more information about PID tuning software like INCATools PID Tuner? Schedule a meeting with one of our control experts. We are happy to help you with information tailored to your needs. Talk to an expert today!

Or do you want to know what INCATools PID Tuning can offer you? Request your demo here.