In the blog post “Intermediate Variables in APC”, it was explained how Advanced Process Control (APC) applications can benefit from the use of intermediate variables. In this second blog, further potential for improvement is presented. If the concept of intermediate variables is new to you, check the previous blog first.

Advanced Process Control (APC) applications rely on models that accurately describe the process behaviour. The modelled response of one or more controlled variables (CVs) to a setpoint change in a manipulated variable (MV) is used to predict these CVs over the prediction horizon. The prediction horizon is usually several hours. Next, optimal setpoint moves are calculated for manipulated variables and a feedback mechanism ensures that the predictions stay in tune with reality.

Non-linearities – an invisible enemy of your PID control loops

PID control is widely used for process control across various industries. However, PID control performs well if the process behaviour is almost linear, which is not the case most of the time. Non-linearities are quite common in practice, although they are often not properly identified or considered for the design of the control system.

Topics: PID tuning, PID tuning software, Advanced Process Control

Cross-limiting Control is implemented, what’s next?

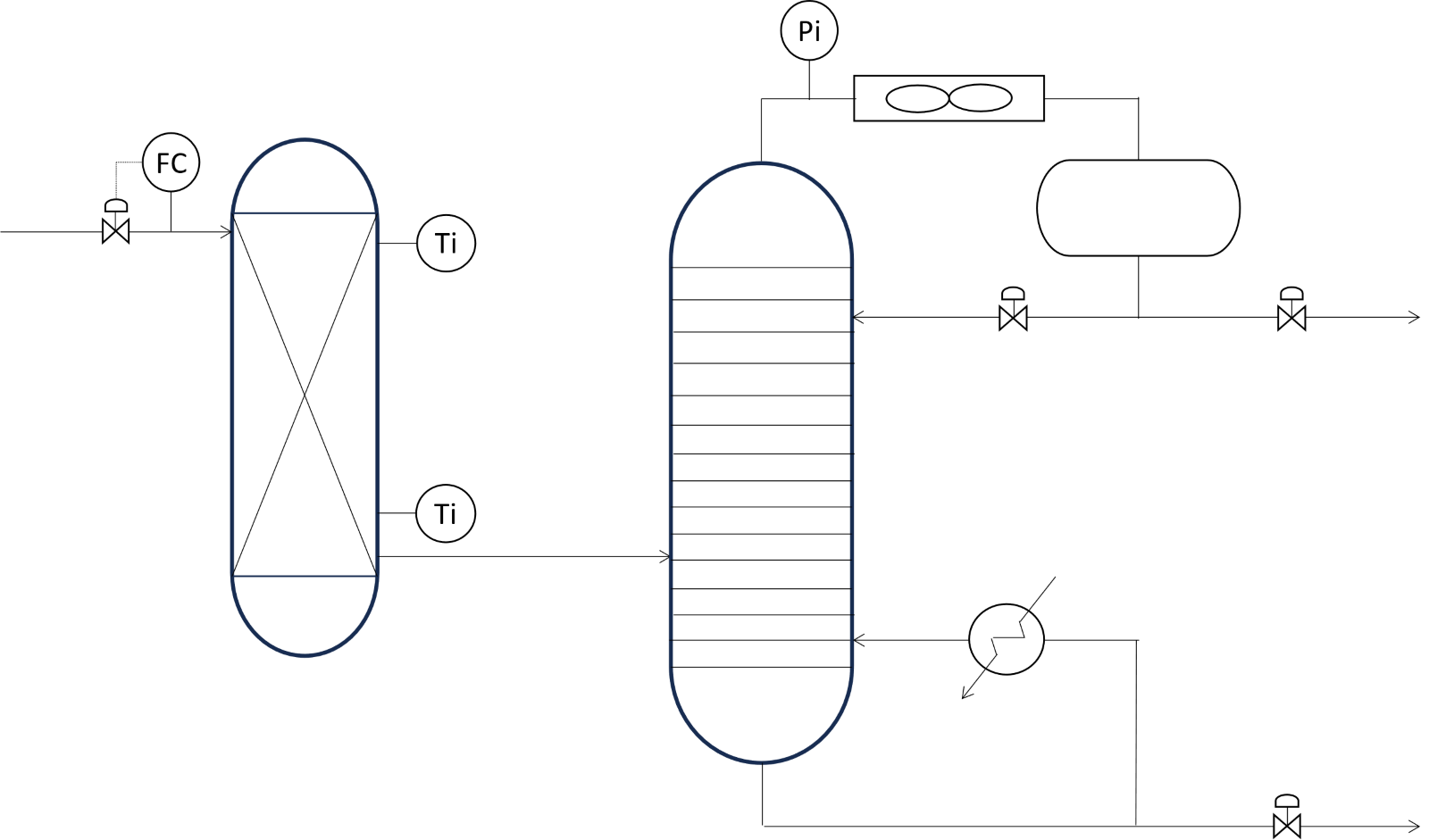

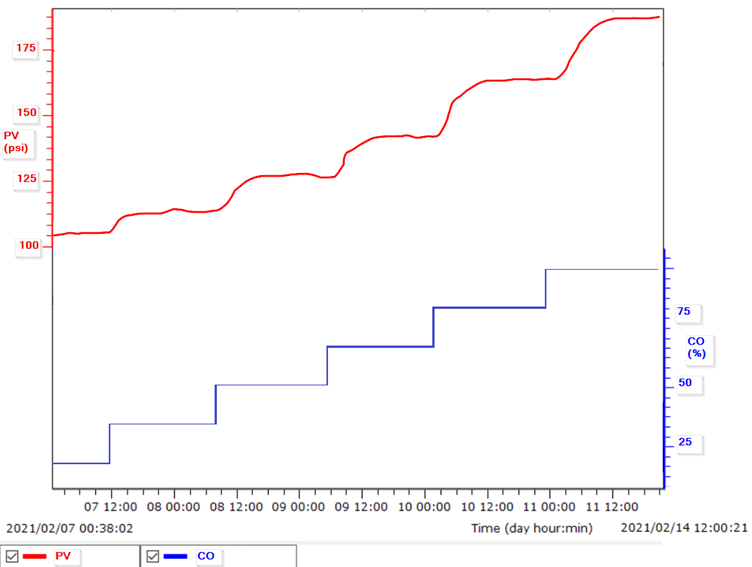

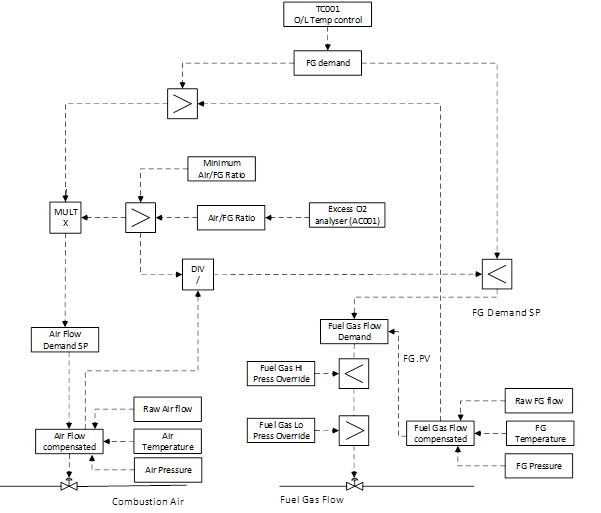

The cross-limiting control schemes are utilized in furnaces to ensure the airflow never goes below the safe limit. These control schemes are designed so that whenever there is an increase in demand for fuel gas, the airflow will lead fuel gas flow, and in the case of a decrease in fuel gas demand, the airflow will lag the fuel gas flow.

Topics: PID tuning, Plant performance, Advanced Process Control

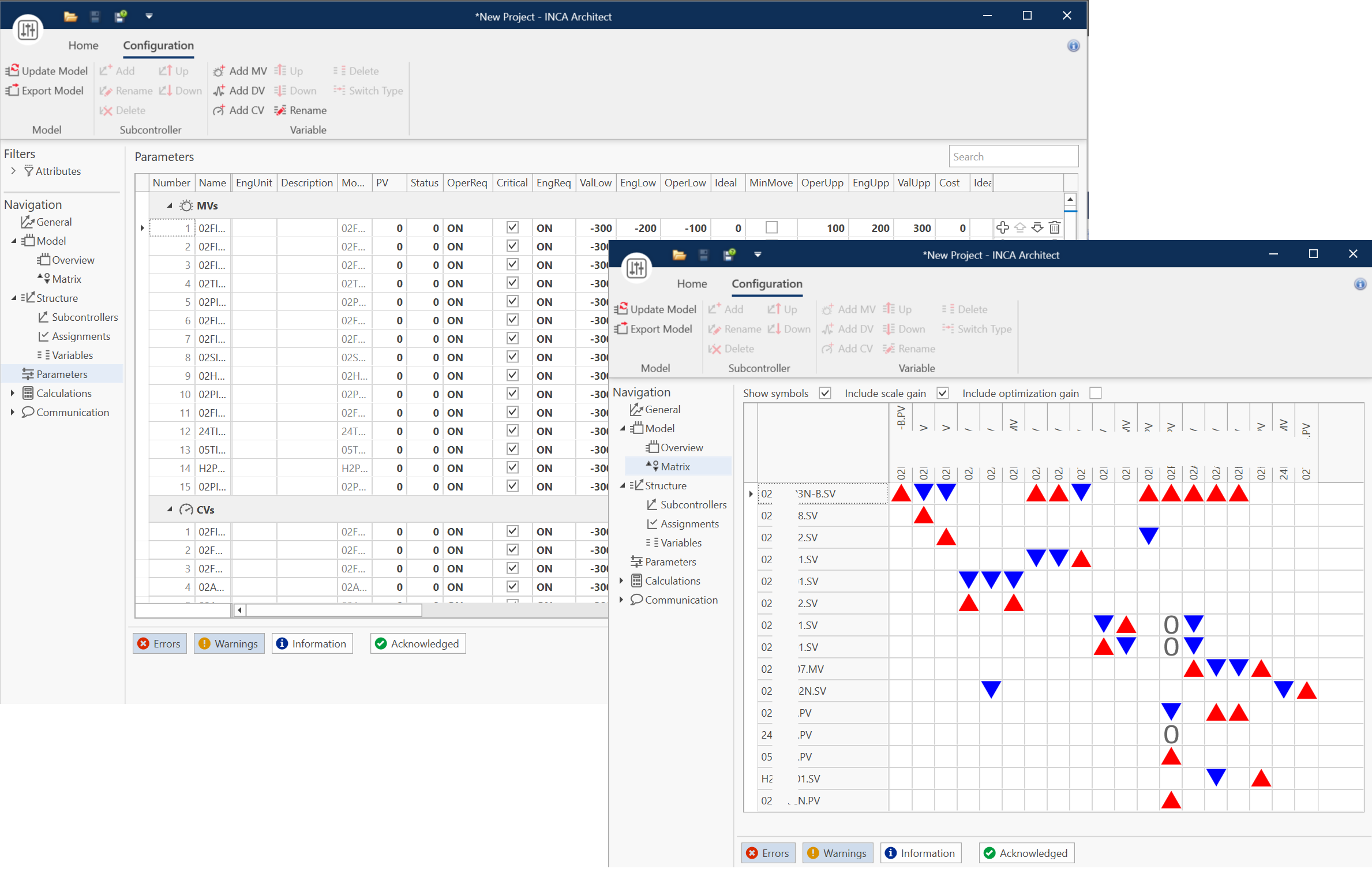

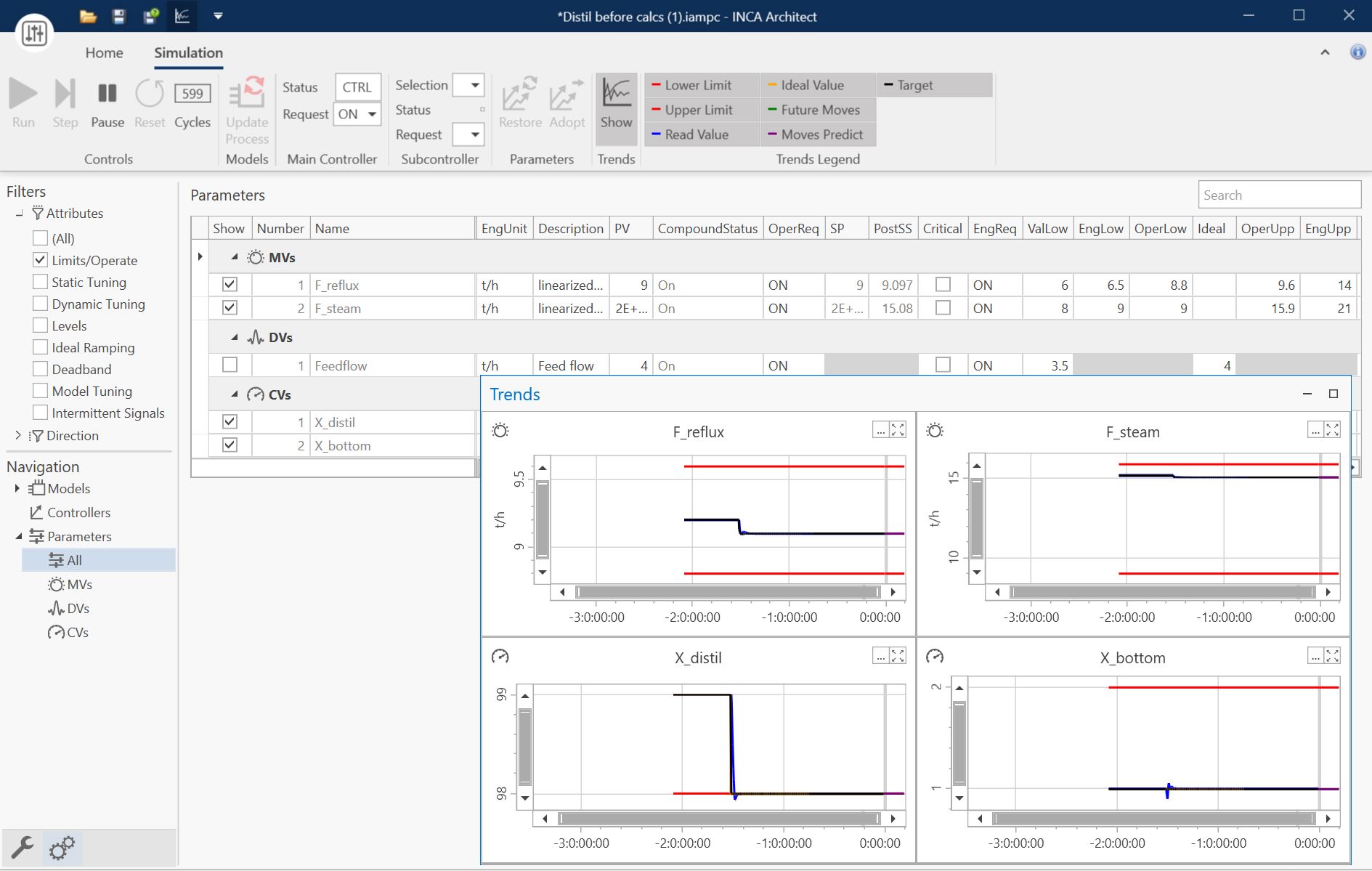

How to configure an MPC controller with INCA Architect

Once installed, INCA MPC has proven to generate sustained benefits for operating companies. To configure INCA MPC, you need to take several steps: choose the targets and constraints, determine the controller structure, set up the communication between the controller and the process, and tune the controller… After the first version of the controller, updates will be needed later. These updates range from tweaking a tuning parameter to adding extra variables to the controller and updating the targets. All these steps must be executed carefully. The iterations involved in finding mistakes slow down the project’s progress.

Topics: Advanced Process Control

An earlier blog described how INCA Architect makes configuring an INCA MPC application easy by automating tasks, grouping related information and continuously monitoring the consistency and validity of the configuration.

But what if your situation is non-standard? Can you also use the INCA tools in that case? Can you verify the correct behavior of your configuration before going online? This blog discusses how the combination of INCA MPC and INCA Architect gives you all the tools to tackle these cases too!

Topics: Advanced Process Control

Why you should implement soon after awarding an APC project

Operations managers have many priorities to juggle in their workday. Some of these activities are completing emergency repairs, resolving instrumentation issues, meeting production targets, preparing and presenting reports. When a company purchases a new APC projectit may fall to the bottom of the priority list due to other activities requiring more attention. Why is it important to start APC activities soon after the contract award? What are the convincing arguments for operations managers that will help them move the APC project higher up the priority list and start implementation as soon as possible?

Topics: PID tuning, Advanced Process Control

Low risk investment and guaranteed benefits with APC project

Every operations manager would like to improve the performance of their asset in a safe manner. You need to steer your plant operation through rapid business changes, and maintain products within the specified targets while always maintaining safe plant conditions. Further optimisation of your operation is not feasible with the current tools, and you know that Advanced Process Control (APC) has been successful in making further improvements in similar processes. How do you go about adopting APC for your facility?

Topics: PID tuning, Advanced Process Control

APC: 5 benefits of Advanced Process Control you can generate in your plant - starting this year

Advanced Process Control (APC) carries a raft of benefits. Any competent control engineer can list at least a dozen. That list will often contain only quantitative benefits - emphasizing production yields, feedstock flows, product qualities and the like. There are however also other benefits to advanced process control - benefits less strictly numeric, but nonetheless with a huge impact on operating efficiency.

Topics: Advanced Process Control

How LANXESS Belgium improves control with IPCOS process control tools

Leading specialty chemicals company, Lanxess Belgium, noticed the plant wasn’t working at its full potential. Many controllers were underperforming and in manual mode. Due to lack of time, the control engineers ran aground to complete optimization. Read in this blog what benefits they gained by using the INCATools software, or download the case study to discover the process and results.

Topics: PID tuning, Advanced Process Control