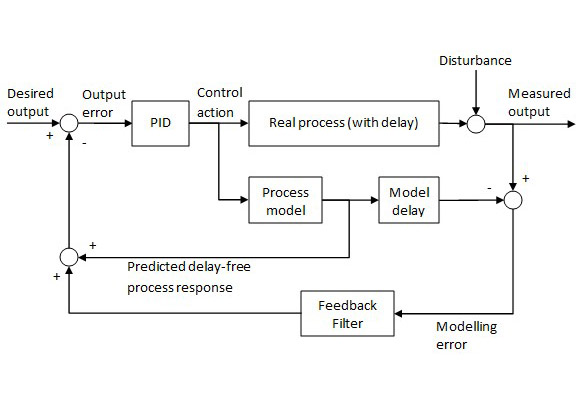

From refineries to petrochemical and chemical industries, the Smith predictor is used to improve the control of processes with a long dead time. The delayed behavior of the process is compensated by using an approximated model in the control structure. It is common for process control engineers to evaluate the need for such control structures and keep them performant. This blog explains the consequences of a long process dead time and what tools to use when tuning your Smith Predictor.

Smith Predictor: when to use it and how to tune it

Topics: PID tuning, PID tuning methods, PID control equations

Comparison of different tuning methods with INCA Aptitune

The tuning of Proportional-Integral-Derivative (PID) can be considered a mix of art and science. It's an art where one needs to use their judgment and experience to understand the controller’s behavior. The science of tuning comes into the picture where one uses open-loop mathematical models and different techniques to derive the tuning parameters. The “Art” of tuning helps to understand the how’s and why’s of the process, and the “Science” of tuning provides a roadmap for tuning.

The performance of any PID controller depends on tuning parameters, i.e., gain, integral time, and derivative time that is set in. The tuning parameters are a function of process types, functionality expected from the PID loop, i.e., variance reduction or setpoint tracking, and type of the PID loop.

Topics: PID tuning methods

Steam drum is a vital part of boiler system in chemical industries. Proper and safe functioning of boiler depends on various parameters such as level of steam drum, flow of feedwater and flow of steam. The pressure, temperature and level of boiler system cannot be regulated directly but depends on the feed-water flow. The pressure or temperature in a boiler system can be maintained by controlling the flow of fuel and air whereas the level can be maintained by regulating the flow of feed water. The purpose of drum level controller is to keep the level at desired value, optimal interface level requires between steam and water within the steam drum. It is essential that the level of liquid must be low enough to assure that there is appropriate separation between steam and water and high enough to guarantee that the water exists in every steam generating tube.

In this blog we will show the 3 most common drum level control schemes and what tuning strategy you should adopt for every strategy.

Topics: PID tuning, PID tuning methods

PID Derivative: Don’t be afraid of the D (in PID tuning)

Why and when use Derivative in PID control? The vast majority of PID controllers are tuned with Proportional and Integral action only, while in some cases controller performance could be improved by including the D-action. Read in this blog what derivative action is and what to expect of the webinar ‘Don’t be afraid of the D’.

Topics: PID tuning methods

Best PID tuning methods explained for level loops: Part 2

In this blog we are going to compare different tuning techniques used to tune the level loops in a distillation column. The tuning methods under consideration are Lambda, the Zak Friedman tuning rules and AptiTune. The idea is to obtain a tuning based on engineering specifications like maximum deviations, minimal gain and dead-time margin.

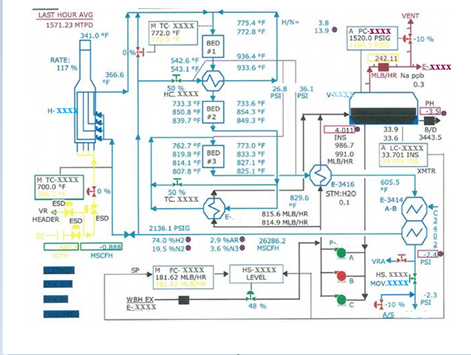

The following distillation column example illustrates the tuning strategies that can be applied when designing the controller for level loops. A debutaniser is used to separate the C4 (isobutane, n-butane) from a natural gas liquids stream (NGL). In this example, there are 4 cascade loops, for the column pressure, the top temperature, and the column bottom and reflux drum levels. There are also single loops for the feed and steam flow. The piping and instrumentation diagram is presented the figure below:

Topics: PID tuning methods

Best PID tuning methods explained for level loops: Part 1

You reviewed all important PID loops on your process, and they all seem to work well. You selected some of the loops and followed the tuning procedure to update the PID parameters and with proper tests and models, you managed to apply the known tuning rules so the fast response to SP changes could be achieved. So, there is nothing else to worry about, right? You might have unnoticed some of the loops.

Even though this recipe could be adequate for many of the loops, provided other important criteria are also taken into account, as process objectives, restrictions, and characteristics of actuators, this is not always true, especially for level loops. Two different types of strategies can be distinguished depending on the control objective:

Topics: PID tuning methods

At most plants, the biggest challenge in tuning PID controllers is to reject process disturbances. However, in many PID controller’s information regarding process disturbances is missing in the PID algorithms which drastically affects PID performance. Do you need to understand how to add that information in PID controllers? Check out this blog, about the benefits in feedforward in PID controllers.

Topics: PID tuning, PID tuning parameters, PID tuning methods

When the Ziegler-Nichols PID tuning method doesn’t do the trick

Many tuning methods are proposed for PID controllers, of which trial and error is the best known and used method. Despite its popularity, the biggest downside is that it’s time-consuming and it doesn’t guarantee a robust and stable solution. The Ziegler-Nichols method is a good alternative but doesn’t always provide optimal performance. In this blog, you will read why Ziegler-Nichols isn’t always the right choice to achieve stable and robust control loops.

Topics: PID tuning methods

PID tuning example: Controller with a nonlinear response on the valve

When we work with PID controllers, we always assume that the control valve flow characteristic is linear. PID controllers cannot handle nonlinear responses properly. However, most of the time valves are nonlinear and we have to deal with them when tuning a loop. Process units that change their operating window regularly, have the tendency to affect the performance of the PID controllers. This probably has happened to you before and i know it's really frustrating! But I'll show you a PID tuning example where it's possible to tune a PID controller and have a good performance on a large operating window of a process unit. And that is what I will explain in this blog.

Topics: PID tuning, PID tuning parameters, PID tuning methods

Topics: PID tuning, PID tuning parameters, PID tuning methods