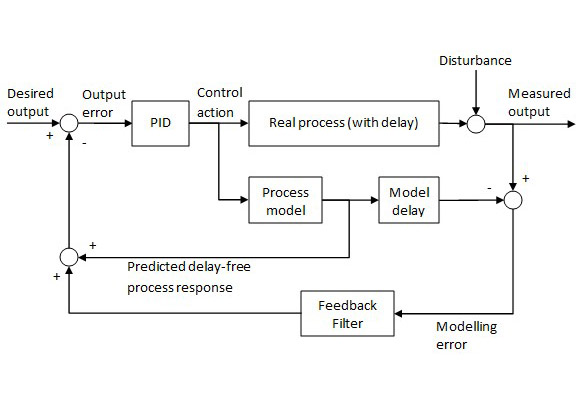

From refineries to petrochemical and chemical industries, the Smith predictor is used to improve the control of processes with a long dead time. The delayed behavior of the process is compensated by using an approximated model in the control structure. It is common for process control engineers to evaluate the need for such control structures and keep them performant. This blog explains the consequences of a long process dead time and what tools to use when tuning your Smith Predictor.

Didac Recio

Recent Posts

Smith Predictor: when to use it and how to tune it

Topics: PID tuning, PID tuning methods, PID control equations

What if you could increase your return on investment, safety, and overall plant efficiency with just one optimization? Furnace control is often disregarded as furnaces are considered as subunits that are not important to optimize. However, one cannot underestimate the impact of the furnace performance on the overall unit. In this blog, we'll explain what the consequences of bad furnace control are, what the results of optimization will be and how to tune your furnace correctly.

Topics: PID tuning

PID Tuning Example: How to do PID tuning for interacting loops?

Tuning of PID controllers has shown to improve plant performance and increase stability and safety. Very often, single control loops are tuned with the focus only on that specific loop, without regard for process interaction with other control loops. Depending on the nature of the process, this interaction can lead to a destabilizing effect where the control loops fight each other instead of working together in harmony. Discover in this PID tuning example how to analyze and tune interacting loops in this blog.

Topics: PID tuning methods, PID tuning example