Cross-limiting Control is implemented, what’s next?

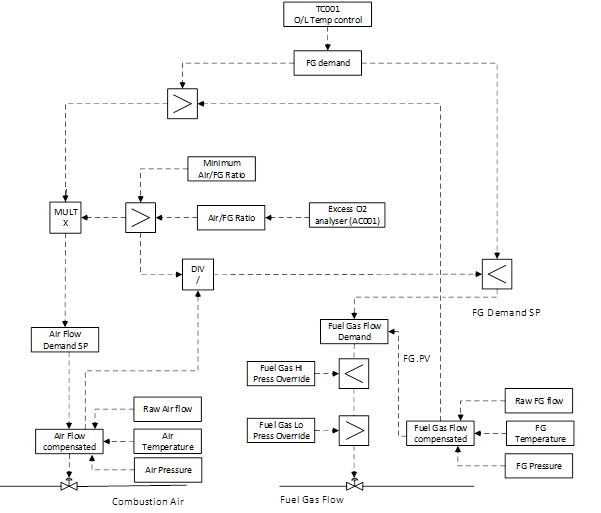

The cross-limiting control schemes are utilized in furnaces to ensure the airflow never goes below the safe limit. These control schemes are designed so that whenever there is an increase in demand for fuel gas, the airflow will lead fuel gas flow, and in the case of a decrease in fuel gas demand, the airflow will lag the fuel gas flow.

Kamalnayan Singh

Recent Posts

Topics: PID tuning, Plant performance, Advanced Process Control

Comparison of different tuning methods with INCA Aptitune

The tuning of Proportional-Integral-Derivative (PID) can be considered a mix of art and science. It's an art where one needs to use their judgment and experience to understand the controller’s behavior. The science of tuning comes into the picture where one uses open-loop mathematical models and different techniques to derive the tuning parameters. The “Art” of tuning helps to understand the how’s and why’s of the process, and the “Science” of tuning provides a roadmap for tuning.

The performance of any PID controller depends on tuning parameters, i.e., gain, integral time, and derivative time that is set in. The tuning parameters are a function of process types, functionality expected from the PID loop, i.e., variance reduction or setpoint tracking, and type of the PID loop.

Topics: PID tuning methods