Buffer tanks are built to provide smoother operation to the process, avoiding the propagation of disturbances on the inputs, e.g., temperature, composition, feed rate, to the downstream process. Aggressive tuning methods don't work for buffer tanks since you want to explore the largest volume possible to reduce the disturbances. In this blog, we will explain how you make a compromise with the correct tuning.

Gustavo Müller

Recent Posts

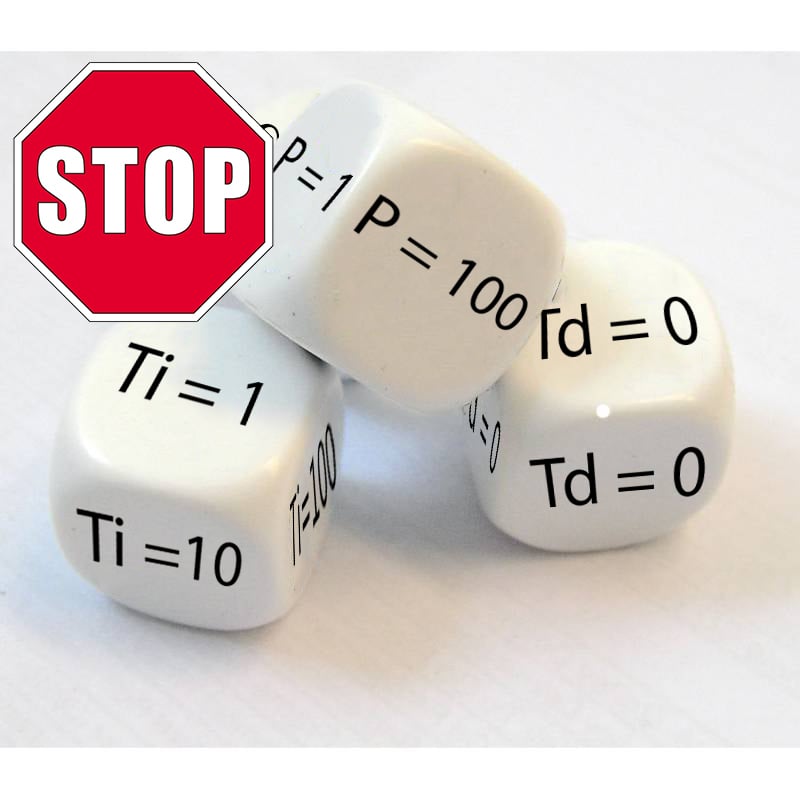

Topics: PID tuning

Best PID tuning methods explained for level loops: Part 2

In this blog we are going to compare different tuning techniques used to tune the level loops in a distillation column. The tuning methods under consideration are Lambda, the Zak Friedman tuning rules and AptiTune. The idea is to obtain a tuning based on engineering specifications like maximum deviations, minimal gain and dead-time margin.

The following distillation column example illustrates the tuning strategies that can be applied when designing the controller for level loops. A debutaniser is used to separate the C4 (isobutane, n-butane) from a natural gas liquids stream (NGL). In this example, there are 4 cascade loops, for the column pressure, the top temperature, and the column bottom and reflux drum levels. There are also single loops for the feed and steam flow. The piping and instrumentation diagram is presented the figure below:

Topics: PID tuning methods

Best PID tuning methods explained for level loops: Part 1

You reviewed all important PID loops on your process, and they all seem to work well. You selected some of the loops and followed the tuning procedure to update the PID parameters and with proper tests and models, you managed to apply the known tuning rules so the fast response to SP changes could be achieved. So, there is nothing else to worry about, right? You might have unnoticed some of the loops.

Even though this recipe could be adequate for many of the loops, provided other important criteria are also taken into account, as process objectives, restrictions, and characteristics of actuators, this is not always true, especially for level loops. Two different types of strategies can be distinguished depending on the control objective:

Topics: PID tuning methods

Topics: PID tuning, PID tuning parameters, PID tuning methods