We often don't have the time to sift through information on new products, especially when under pressure to find solutions for ongoing problems. To help you discover INCATools AptiTune, we've compiled a list of options to choose from to fit your busy schedule.

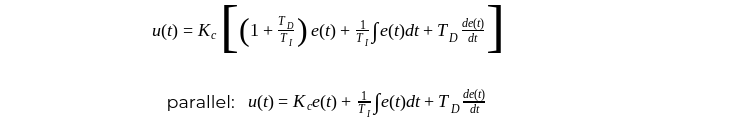

INCATools is a suite of process control tools that contains some of the most powerful PID tuning instruments on the market. INCATools AptiTune is the tool to be used to tune ALL your PID controllers: the easy, the tough, the non-interacting and the interacting ones.

To learn more about INCATools AptiTune, you can download a demo version of the software or request a live demo with one of our Control experts.

.jpg)

.jpg)