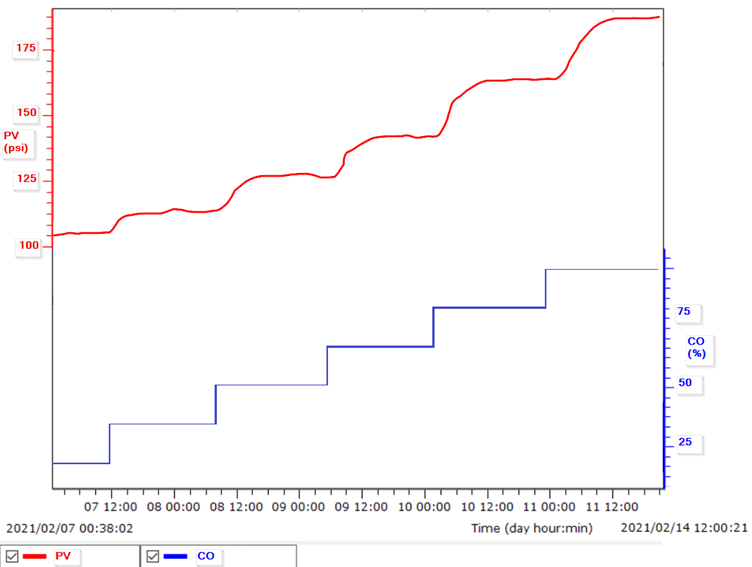

PID control is widely used for process control across various industries. However, PID control performs well if the process behaviour is almost linear, which is not the case most of the time. Non-linearities are quite common in practice, although they are often not properly identified or considered for the design of the control system.

Julian Vidal

Recent Posts

Non-linearities – an invisible enemy of your PID control loops

Topics: PID tuning, PID tuning software, Advanced Process Control

How to approach a PID tuning project in a phased way

Many operations managers face a challenge to maintain all PID loops on their plant in good working order. Plant safety may be at stake in some cases if some of these PID loops are kept in manual mode. Poor PID tuning may also contribute towards degradation in plant performance, leading to unstable operation and, eventually, reduced profitability. Operations managers need to create a culture of continuous PID performance monitoring and improvement, ensuring safe and optimal plant performance. How do you embark on this journey, and what are the best practices?

Topics: PID tuning

Large processing facilities such as Refineries and Chemical plants spend money on technology to enhance process performance. Metrics are typically put in place to measure how well the technology is performing, and control engineers are required to report on these metrics regularly. There are thousands of PID loops on a typical refinery; what strategy should you use to identify poor performers and then rectify the issues?

How do you ensure that the reported metrics provide your management a full and clear picture of PID loop performance?

Topics: PID tuning

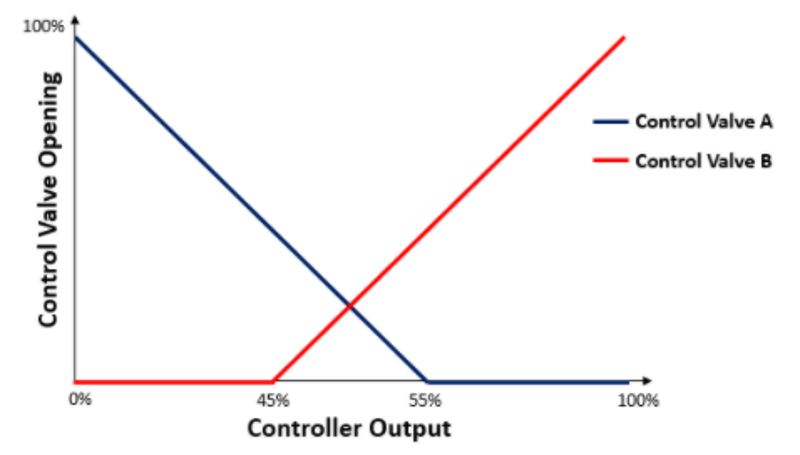

How to Successfully Configure and Tune a Split Range PID Control Strategy and Not Die Trying

A split range control strategy uses software or hardware-based splitter and two or more final control elements to control a process variable. Split range strategies can be found in different applications across process industries: temperature control with heating/cooling media, large and small valves installed in parallel, pressure control with a vent valve, etc.

Usually, split range applications are tricky and time-consuming, and you should know what I’m talking about as a process control engineer

Oscillations over the entire range of operation and across the split point, typically improperly selected at 50%, are common in real operation.

In this blog, we will discuss the usual problems you might face when configuring and tuning a split range strategy and the possible and practical solutions to overcome it.

Topics: PID tuning

Temperature Control for Batch Reactors in your industry

Batch reactors are used to produce a variety of products in all sectors of process industries, especially in the pharmaceutical, specialty chemicals, wastewater treatment and the beverage sector. The flexibility to use the same equipment to produce different products sometimes makes batch reactor difficult to control. If we add to this the integrating/runaway process response, suboptimal PID control loop tuning, poor control loop elements performance, and an inappropriate process and control design,we might have the perfect recipe for disaster. If you want to learn more about obtaining optimal batch reactor temperature control, keep reading the blog.

Topics: PID tuning