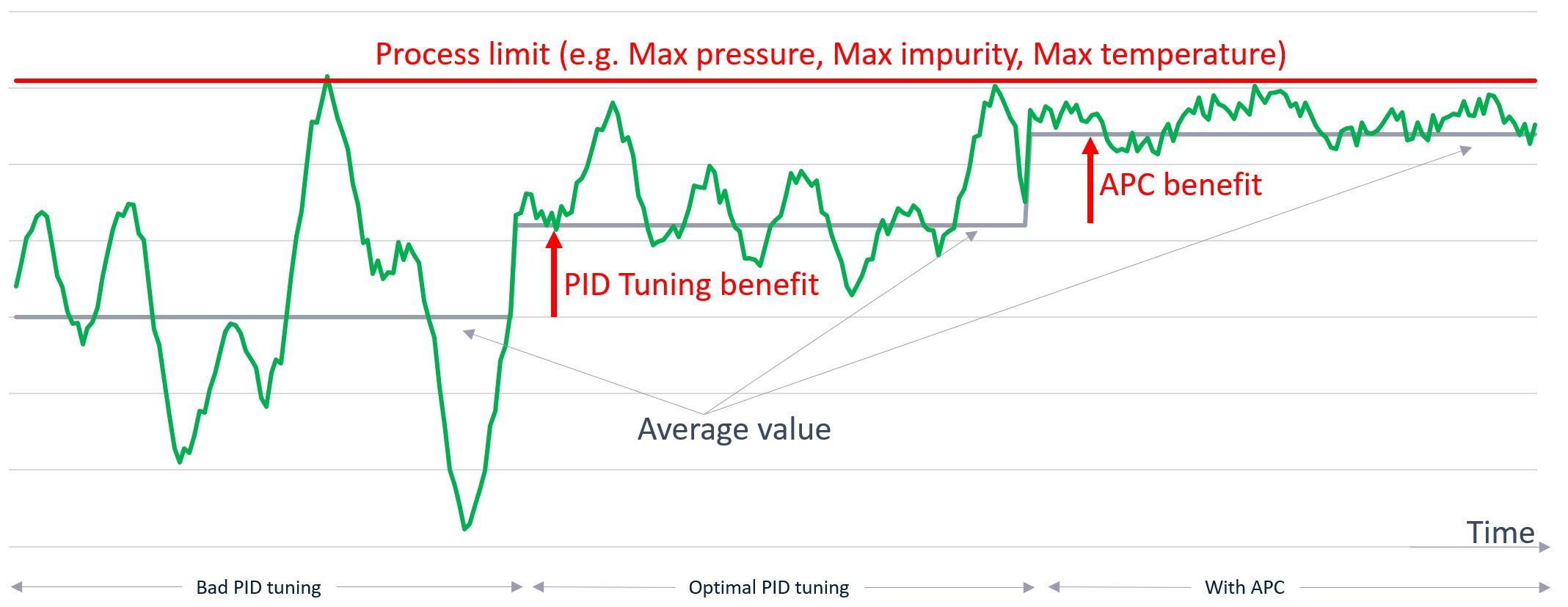

It's no secret that proper PID tuning will contribute to a stable plant with fewer variations and fluctuations. Optimal and stable operations are the ultimate goal. This can result in several percentages of extra throughput and several percentages reduction of specific energy consumption. Additional throughput is highly desired in high market conditions, while the specific energy consumption might be more interesting when selling prices are low and energy prices high. In all cases, more stability results in fewer alarms and fewer operator interventions.

In this blog, you will learn why PID tuning improves process performance and how to accomplish this technical result of PID tuning.

Plant performance will increase by professional PID tuning

Proper PID tuning will contribute to more consistent performance of the plant. The primary goal of a DCS engineer is to achieve flat line temperatures and flat line pressures in the controller, or at least to get as close to flat line operations as possible. Once the flat line conditions are approached you can aim for optimal plant operations. Your goal as a plant operator is meeting the targets set by the headquarters regarding safety, throughput and energy. Plant stability will contribute to these targets.

Example PID tuning for process performance

If you have a plant with thousands of PID loops in the DCS systems it will be time-consuming to tune all loops optimally. Pick your battles and focus on the important ones. As an example; five to six PID controllers control a distillation column. If the DCS engineer manually tunes the controllers one by one and sets them all in automatic mode they might start interacting or counteracting with each other. In case of counteracting, individual tuning might bring you further from the optimal performance working point.

Six building blocks for plant process performance

To achieve high process performance in your plant PID tuning is essential. PID tuning software helps you to tune the PID loops faster and more efficiently. Once the PID loops are tuned with the help of a PID tuning software, you can put the controllers in automatic mode. You won't have to worry about it again and will save you a lot of time on a daily basis.

Six building blocks will contribute to a higher process performance of your plant. They are described below:

1. More throughput in high market conditions

By making sure the PID controllers are tuned well, and in automatic mode, the systems can lavish towards the limits of the plant. By reaching this full capacity, the plant can increase its production.

2. Higher energy efficiency and more profit

By tuning the PID controllers properly, you can increase energy efficiency. The amount of specific energy will be reduced. High energy efficiency will increase the plant's profit. Sometimes higher throughput and lower specific energy consumption go hand in hand. That is a double bonus.

3. Longer run lengths of the plant

If your plant runs smoothly because of proper PID tuning, there will be less wear and tear of your valves. It will result in less unforeseen repair costs and shutdowns. Where you used to have 12 shutdowns in one year now the plant can run uninterrupted for several years in a row or until the next catalyst change. The results are not all due to tuning, but tuning might help a lot in achieving these multi-year run lengths.

4. Operator ease because of fewer alarms in the DCS

If the PID controllers are in automatic mode, it will take up no time for your operators. The disturbances mitigates the valve and the plant will run smoothly again afterwards. A smooth-running plant will result in fewer alarms and more operator ease.

5. Higher quality of the product

When there are fewer fluctuations and variations, it will result in a higher consistency of the quality of your product. When quality is perfectly controlled, it becomes possible to operate closer to, for example, impurity limits, resulting in reduced energy costs.

6. Reaching the plants daily targets

In modern markets, the target of the plant can change very frequently, even on a daily basis. For example, targets like production quantities and product grades change often. It makes it very difficult in combination with changing feedstocks and varying energy prices to operate at all times at the optimal working point. Typically it's the task of Advanced Process Controllers to help operations to reach the changing targets. But it all starts with optimal PID controllers. To reach the target, you need help from a PID tuning software to run the plant smart and capitalize on the demand.

Smart tuning with PID tuning software

A PID tuning software like INCATools PID Tuner helps you to realize higher process performance in your plant. It's designed to set the PID parameters right at once, so the PID controllers can be set to automatic mode. The right PID parameters form the basis for Advanced Process Control and further optimization of the plant.

Choose a PID tuning software that suits your needs

The plant production numbers have a direct impact on company performance. Aiming for the highest possible performance can be stressful. Juggling between plant safety and stability, happy crew members and maximum performance that comply with the production targets.

The main benefit of using PID tuning software is that it allows the DCS engineers to quickly identify under-performing loops and simplify the reproducibility of the tuning results. The software will calculate the right parameters and provide them with an automatically documented project file per PID loop.

All in all, PID tuning software offers stability and higher plant performance, and it results in less wear and tear of the equipment. Are you interested to see what more benefits a PID tuning software can offer you? Request a 30-minute live demo and learn how you can improve your plant process performance. Request your demo here:

Do you like to know what INCATools PID tuning software can offer you?

Request your demo here.