Large processing facilities such as Refineries and Chemical plants spend money on technology to enhance process performance. Metrics are typically put in place to measure how well the technology is performing, and control engineers are required to report on these metrics regularly. There are thousands of PID loops on a typical refinery; what strategy should you use to identify poor performers and then rectify the issues?

How do you ensure that the reported metrics provide your management a full and clear picture of PID loop performance?

Topics: PID tuning

How to Successfully Configure and Tune a Split Range PID Control Strategy and Not Die Trying

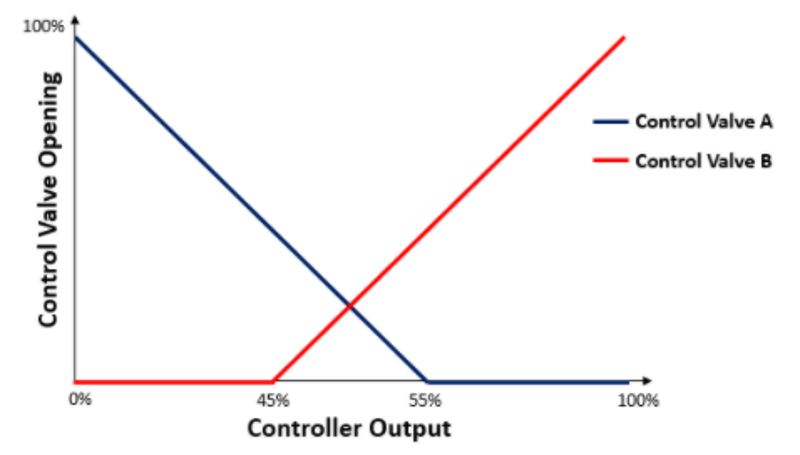

A split range control strategy uses software or hardware-based splitter and two or more final control elements to control a process variable. Split range strategies can be found in different applications across process industries: temperature control with heating/cooling media, large and small valves installed in parallel, pressure control with a vent valve, etc.

Usually, split range applications are tricky and time-consuming, and you should know what I’m talking about as a process control engineer

Oscillations over the entire range of operation and across the split point, typically improperly selected at 50%, are common in real operation.

In this blog, we will discuss the usual problems you might face when configuring and tuning a split range strategy and the possible and practical solutions to overcome it.

Topics: PID tuning

We often don't have the time to sift through information on new products, especially when under pressure to find solutions for ongoing problems. To help you discover INCATools AptiTune, we've compiled a list of options to choose from to fit your busy schedule.

INCATools is a suite of process control tools that contains some of the most powerful PID tuning instruments on the market. INCATools AptiTune is the tool to be used to tune ALL your PID controllers: the easy, the tough, the non-interacting and the interacting ones.

To learn more about INCATools AptiTune, you can download a demo version of the software or request a live demo with one of our Control experts.

Topics: PID tuning software

Temperature Control for Batch Reactors in your industry

Batch reactors are used to produce a variety of products in all sectors of process industries, especially in the pharmaceutical, specialty chemicals, wastewater treatment and the beverage sector. The flexibility to use the same equipment to produce different products sometimes makes batch reactor difficult to control. If we add to this the integrating/runaway process response, suboptimal PID control loop tuning, poor control loop elements performance, and an inappropriate process and control design,we might have the perfect recipe for disaster. If you want to learn more about obtaining optimal batch reactor temperature control, keep reading the blog.

Topics: PID tuning

There are many critical PID loops in an operating plant. Operations managers typically like to minimise changes on tuning parameters on such PID loops, quite often maintaining the status quo, even if improvements are possible or desirable. The performance of such PID loops could be optimised if they could be inserted in manual mode followed by moving the output a few times, collecting data, and calculating PID tuning using PID tuning software. Unfortunately, operations managers may not allow you to insert this critical loop in manual, so how can you calculate PID tuning parameters for such a loop while maintaining it in closed-loop mode? In this PID tuning example, we’ll show the best practices and pitfalls.

Topics: PID tuning

Why you should implement soon after awarding an APC project

Operations managers have many priorities to juggle in their workday. Some of these activities are completing emergency repairs, resolving instrumentation issues, meeting production targets, preparing and presenting reports. When a company purchases a new APC projectit may fall to the bottom of the priority list due to other activities requiring more attention. Why is it important to start APC activities soon after the contract award? What are the convincing arguments for operations managers that will help them move the APC project higher up the priority list and start implementation as soon as possible?

Topics: PID tuning, Advanced Process Control

Ratio control is an essential element in the toolbox of control engineers to control various industrial processes. The objective is to maintain the ratio of two flows at a specified value. The desired ratio can be either manually entered by an operator or automatically set by another controller. At least one of the flows needs to be controlled by a PID controller (or at least a valve should be available to control the flow). The ratio can be calculated based on the flow measurements or based on the setpoints of the flow controller(s). The ratio controller can be configured in different ways in the DCS. The different approaches and their pro’s and con’s are described in this blog.

Topics: PID tuning

How to configure PID structures for distillation columns

As a control engineer, you may get called by plant operators when a PID loop is a “bad actor”, causing problems on a distillation column. The process upset caused by this PID loop may have a destabilising impact on downstream process units as well, potentially causing widespread impact. Quite often, the “quick fix” for process operators is to insert these bad acting PID loops in manual. While this mitigates the immediate issue, the cost of such actions is poor performance of the distillation column. The control engineer is tasked with rectifying the problem. Is this a PID tuning issue or are the PID loops on the distillation column configured incorrectly? How would you ensure that the PID structures on a distillation column are configured correctly? You can read it in this blog.

Topics: PID tuning

How to successfully configure and tune a split range PID control strategy

A split range control strategy uses software or hardware-based splitter and two or more final control elements to control a process variable. You can find split range strategies in different applications across process industries such as temperature control with heating/cooling media, large and small valves installed in parallel, pressure control with a vent valve, etc.

Usually, split range applications are tricky and time consuming, and you should know what I’m talking about as a process control engineer.

Oscillations over the entire range of operation and across the split point, typically improperly selected at 50%, are common in real operation.

This blog will discuss the usual problems you might face when configuring and tuning a split range strategy and the possible and practical solutions to overcome it.

Topics: PID tuning

Low risk investment and guaranteed benefits with APC project

Every operations manager would like to improve the performance of their asset in a safe manner. You need to steer your plant operation through rapid business changes, and maintain products within the specified targets while always maintaining safe plant conditions. Further optimisation of your operation is not feasible with the current tools, and you know that Advanced Process Control (APC) has been successful in making further improvements in similar processes. How do you go about adopting APC for your facility?

Topics: PID tuning, Advanced Process Control